Planning & design

The key requirement when designing the library was for the building to take the lead as part of an investment program relating to energy efficiency and greenhouse gas emissions.

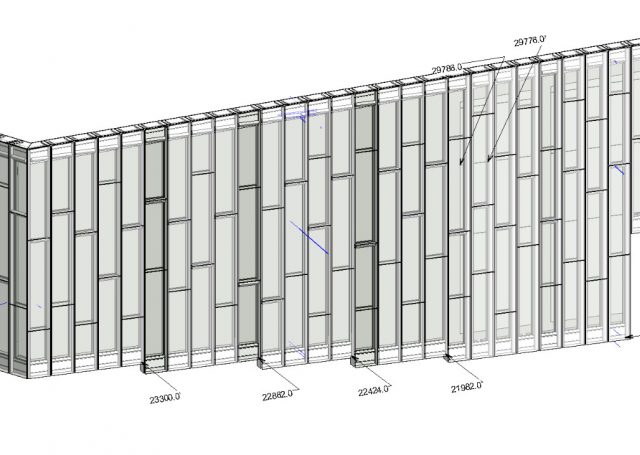

The ground floor facade of the halls and entrance area is a steel post and beam design with triple glazing. The surfaces of the facades on the upper stories, in which the library rooms are located, are realized in a completely new form and material concept.

The facade consists of solid columns with a diameter of approximately 20 inches and central triple-pane insulating glass. This base element has a retaining construction to accommodate panes of laminated safety glass, with lighting features on the inside and outside, which can be opened for cleaning and maintenance purposes. The idea was to design a facade system which can be executed using the element construction method.

The vertical facade columns consist of fire protection-classified, glass fiber reinforced plastic and are filled with heat insulation. The excellent insulating properties of GFRP mean that the facade of the new Oslo Public Library is able to meet high thermal and climatic requirements.

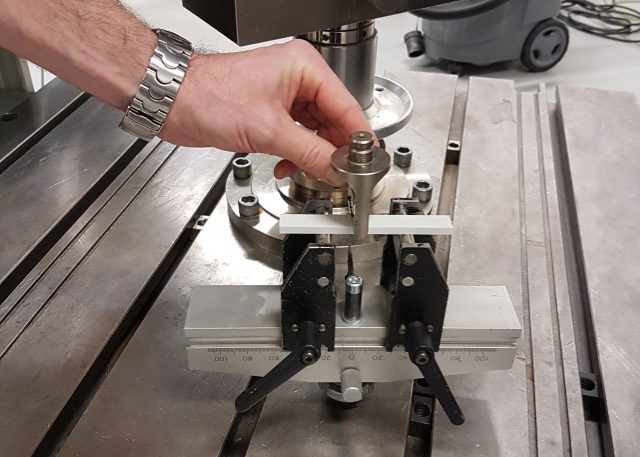

The feasibility of making GFRP facade profiles by extrusion represented a particular challenge. Lengthy trials and test runs on tolerances and surface properties eventually led to the desired outcome.