Planning & design

Where possible, the design of the structure is retained and the existing sealing system is renewed or replaced on the basis of the details available. The glazing must be brought up to date and designed to comply with applicable standards and guidelines.

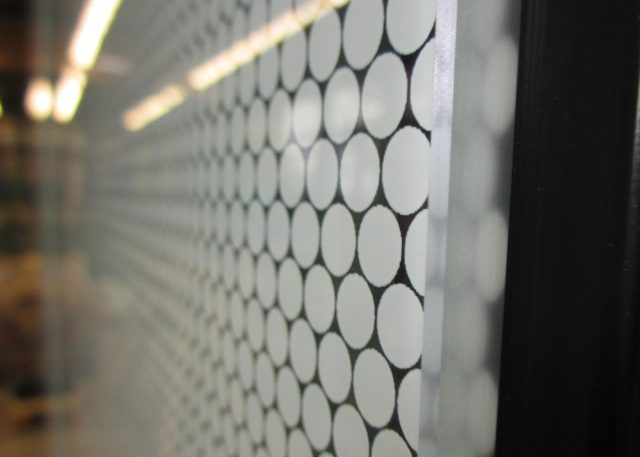

The existing windows with built-in blinds at Haus der Geschichte in Bonn were replaced with double screen printed triple insulating glazing with a shading layer. With an 80% imprint level, screen printing acts as a useful solar shading system while at the same time letting in plenty of daylight.

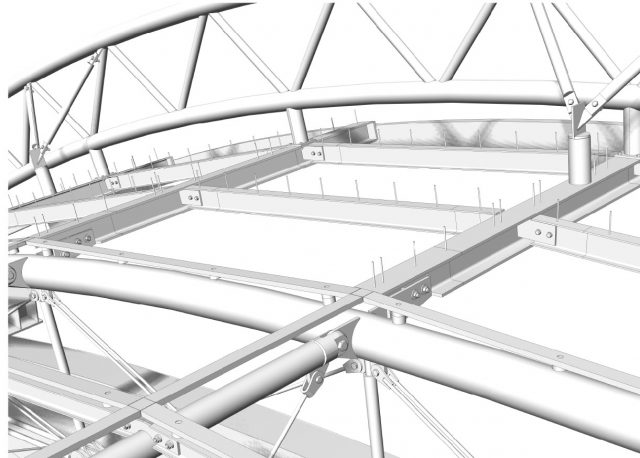

All the options for crane access and storage areas at the building to be refurbished have to be explored. In this particular case a crane was erected on an underground car park roof which had been duly reinforced.

Particular attention had to be paid to the weather conditions during the refurbishment of the roof, not least because exhibits remained in the museum during the building work. The plan provided for suitable temporary weather enclosures to protect the open building from the rain. The materials were stored temporarily on the sides of the roof so as to have the least possible impact on museum operations and keep crane operation to a minimum. To this end a suitable storage area with static support measures was created.