Planning & design

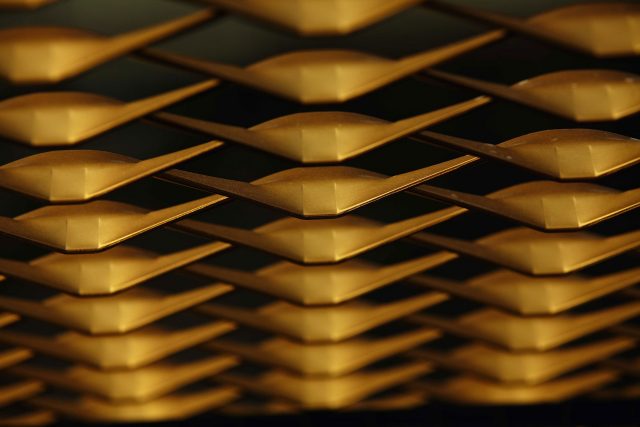

A glass facade was enhanced with a curtain wall made of expanded metal mesh which serves as a sun screen and is adapted to changing lighting conditions. Various mesh sizes were used to take account of the position of the sun throughout the day. The primary requirements for the metal facade were the gold eloxal color scheme and, more particularly, the intersections of the expanded metal struts, which had to be planned in detail.

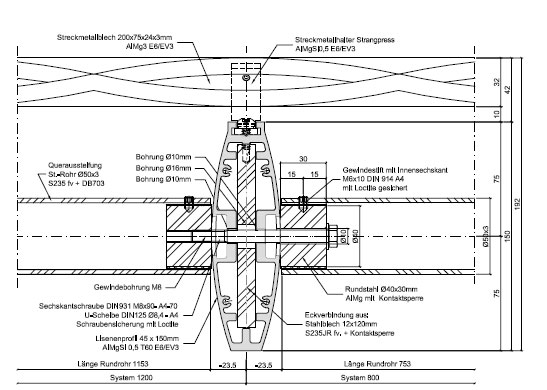

The connections of the individual sheet metal elements had to have the lowest possible tolerances and a homogeneous transition with no offset to the adjoining metal element. To do this, the planners had to record not only the usual facade details, but also all the contours of the edges that were visible on the expanded metal mesh.

The fixings that are invisible from the outside were specially designed, as was the complete substructure, which was made from specially manufactured aluminum profiles.